Advanced Manufacturing: Laser Welding in the Furniture Industry

In a market driven by innovation and efficiency, laser welding offers metal furniture companies a distinct advantage by enhancing profitability, durability, and visual quality.

The technology produces welds so precise that they require minimal finishing, which is the key to these improvements. This leads to faster production cycles, lower labor costs, and greater design freedom, allowing for the creation of more durable and aesthetically refined furniture while boosting manufacturing efficiency.

Design Without Limits: The Impact of Laser Welding on Furniture

Traditional welding methods often forced designers to compromise. Visible, bulky welds had to be hidden or accepted as part of the look. Laser welding shatters those limitations.

Achieving the Minimalist Dream with Invisible Welds

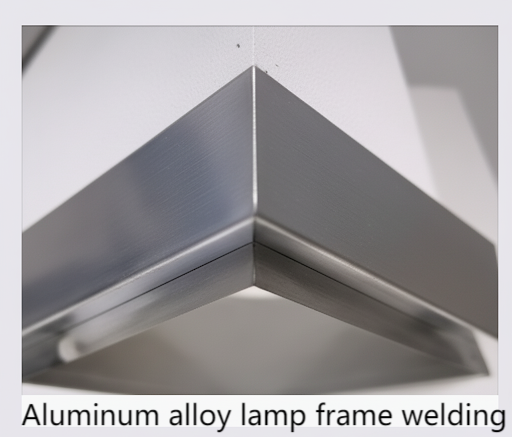

Modern furniture design thrives on clean lines and minimalist aesthetics. Laser welding is the perfect partner for this trend. It creates incredibly smooth, seamless joints that are perfect for high-end furniture where visible welds are unacceptable. The result is a product that looks like it was crafted from a single piece of metal.

Fabricating Intricate Patterns and Geometries

Have you ever wanted to create delicate, complex decorative metalwork? The precision of a laser beam makes it possible. This technology enables the fabrication of intricate patterns and geometric shapes that would be impossible with traditional methods, which often cause heat distortion and ruin fine details.

Innovating with Mixed-Material Furniture

The low-heat input of the laser welding process is another major advantage. This allows metal to be welded very close to other materials like wood, glass, or upholstery without causing damage. This opens up a new world of innovative, mixed-material furniture designs.

A Clearer Choice: Why Laser Welding Outperforms Traditional Techniques

When it comes to metal furniture manufacturing, the choice between laser welding and traditional MIG or TIG methods is becoming increasingly clear.

Speed and Throughput

Time is money on the factory floor. Laser welding is up to 10 times faster than traditional methods. This incredible speed drastically cuts production time per piece, boosts your overall output, and gets products to market faster.

Quality and Finish

Forget the time-consuming secondary steps of grinding, sanding, and polishing. Laser welding produces welds with minimal spatter and a very small heat-affected zone (HAZ). This means the finished product comes off the line nearly perfect, eliminating costly and labor-intensive post-processing.

Strength and Precision

Don’t let the clean look fool you; these welds are incredibly strong. The deep, narrow welds created by a laser are often stronger than the parent material itself. The process is also exceptionally accurate, which reduces material distortion and waste.

Welding Method Comparison: Laser vs. MIG vs. TIG

|

Metric |

Laser Welding |

MIG Welding |

TIG Welding |

|

Speed |

Very High |

High |

Slow |

|

Precision |

Exceptional |

Moderate |

High |

|

Finish Quality |

Excellent (Seamless) |

Fair (Requires Grinding) |

Good (Requires Cleaning) |

|

Post-Processing |

Minimal to None |

Extensive |

Moderate |

|

Operator Skill |

Easy to Learn |

Moderate |

High |

|

Initial Cost |

High |

Low |

Low |

From Frames to Filigree: Real-World Laser Welding Applications

So, how does this technology apply to your actual products? Here are some practical examples:

Structural Components: Easily assemble frames, legs, and supports for tables and chairs with superior strength and perfect consistency every single time.

Decorative Metalwork: Create fine, detailed welds on decorative pieces, like patterned chair backs or artistic table bases, that preserve the full aesthetic value.

Thin Materials & Cabinets: Join thin-gauge sheet metal for cabinets, lockers, and panels without the warping or burn-through common with other methods.

These applications demonstrate that whether the task requires robust structural integrity or intricate decorative detail, laser welding is an adaptable solution. It opens the door to new design possibilities and a higher standard of quality, ensuring that your products are not only built to last but are also crafted to perfection.

Unlock the Power of Laser Welding: Three Keys to a Flawless Start

Adopting laser welding is a powerful upgrade to your production capabilities. To harness its full potential from day one, integrate these foundational principles into your workflow.

Precision is the Foundation of Performance

The incredible accuracy of laser welding begins long before the beam is activated. It relies on a perfect joint fit-up between components. By refining your upstream cutting and forming processes to produce parts with minimal gaps, you set the stage for stronger, cleaner, and more consistent welds.

Purity Unlocks Potential

A pristine surface is essential for a perfect weld. Any oil, dirt, or even the natural oxide layer on aluminum can introduce defects and compromise the joint’s integrity. Instituting a mandatory cleaning and preparation step ensures the laser creates a pure, powerful, and visually perfect seam every time.

A Culture of Safety Drives Success

High-powered lasers demand a proactive approach to safety. Protecting your team is your first priority. This means engineering a safe environment with dedicated, enclosed workstations, managing air quality with effective fume extraction, and equipping every person in the area with certified laser-safe eyewear. A safe operation is an efficient and sustainable one.

Staying Ahead of the Curve: The Future of Automated Welding

The technology is still evolving, pushing the boundaries of what’s possible in metal furniture manufacturing.

The Rise of Robotics and Cobots

Automation is making laser welding even more efficient. Integrating laser welders with robotic arms and collaborative robots (cobots) allows for 24/7 production with unmatched consistency, making the technology more accessible for manufacturers of all sizes.

Smart Manufacturing with AI and Machine Learning

The future is intelligent. According to recent industry reports, AI and machine learning are being integrated into welding systems for real-time quality control, predictive maintenance alerts, and automatic process optimization, ensuring every single weld is perfect.

A New Chapter in Furniture Manufacturing

To sum it up, laser welding is more than just a new tool. It’s a strategic investment that delivers unparalleled aesthetic quality, production speed, and design freedom. It empowers you to deliver visually stunning products with invisible seams, manufacture them at a pace that outmatches competitors, and offer your designers the creative liberty to innovate without restraint. This is your opportunity to secure a position at the forefront of the furniture industry.

Let us show you the tangible benefits for your product line. Reach out to our fabrication experts for a personalized consultation and take the first step toward the future of furniture.