Metal Laser Cutter Welder Parts

Metal Laser Cutter Welder Parts

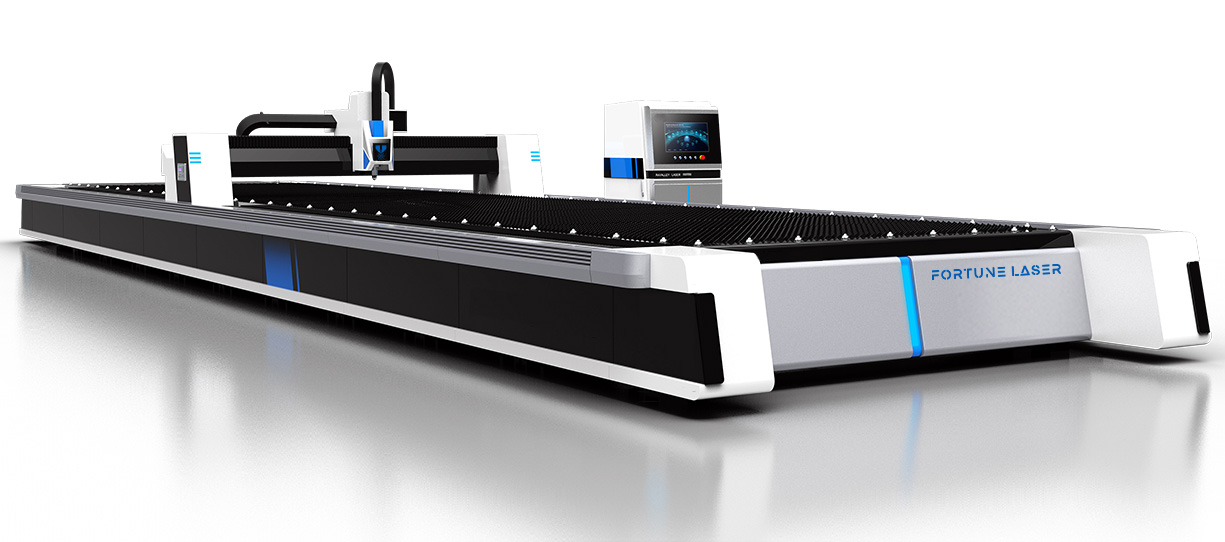

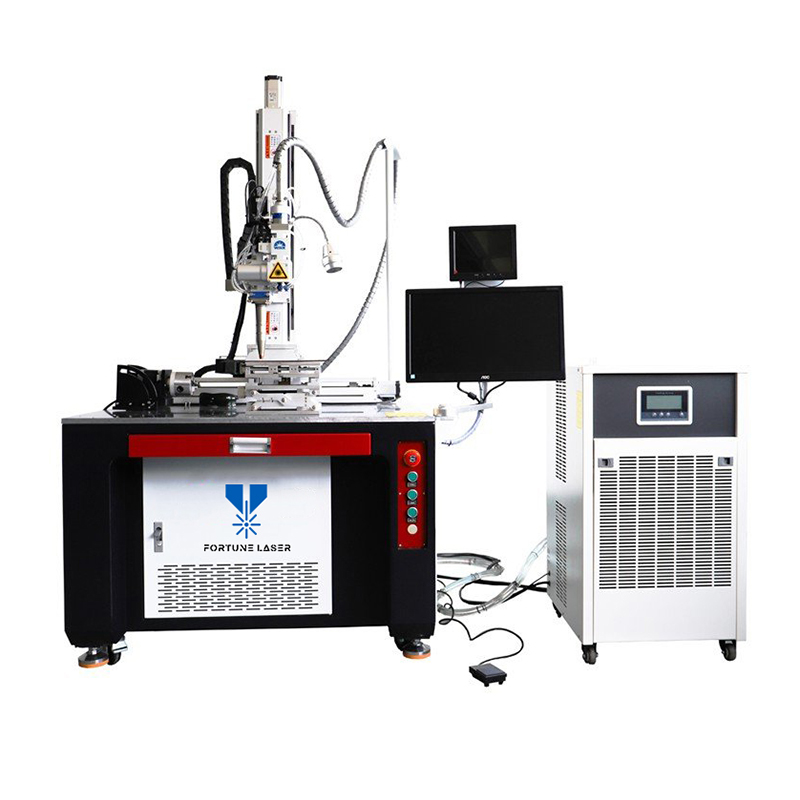

Fortune Laser design and manufacture the whole set of the metal laser cutting machines, the laser welding machines, laser marking machines and the laser cleaning machines. We can also supply the parts for the laser machines as customers required.

ASK US FOR A SUITABLE SOLUTION AND GOOD PRICE NOW!

Laser Source for Laser Cutting Welding Machine

We work closely with top brands of the Laser generator for our laser cutting machines, laser welding machines, laser marking machines and laser cleaning machines, to meet customers’ different requirements and budgets. The brands include Raycus, Maxphotonics, IPG, JPT, RECI, etc.

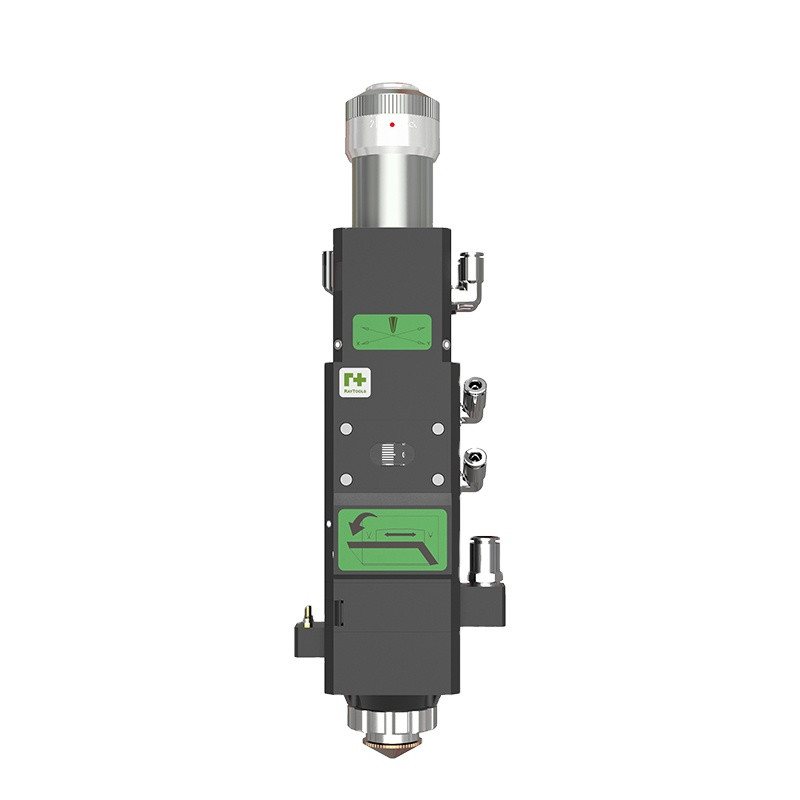

Laser Cutting Head for Metal Laser Cutting Machines

Fortune Laser works closely with some of the top brands laser cutting heads manufacturers, including Raytools, OSPRI, WSX, Precitec, etc. We can not only set the machines with the laser cutting head based on customers’ requirement, but can also provide the laser cutting head directly to customers if needed.

Direct Purchase and Quick Delivery

Genuine Spare Parts and High Quality Guarantee

Technical Support if Any Doubts or Problems

Jewelry Mini Spot Laser Welder 60W 100W

The laser welding heads brands we use for the welding machines are usually OSPRI, Raytools, Qilin, etc. We can also produce the laser welders as customers required.

Laser Cooling System for Laser Cutter Welder

CWFL-1500 water chiller developed by S&A Teyu is made especially for fiber laser applications up to 1.5KW. This industrial water chiller is a temperature control device featuring two independent refrigeration circuits in one package. Therefore, separate cooling from just one chiller can be provided for the fiber laser and the laser head, saving considerable space and cost at the same time.

Two digital temperature controllers of the chiller are desi

6 Main Parts of A Fiber Laser Cutting Machine?

The fiber laser cutting machine is composed of laser generator, cutting head, beam transmission assembly, machine tool table, computer numerical control system and cooling system.

Laser generator

The laser generator is a component that generates a laser light source. For metal cutting, fiber laser generators are currently commonly used. Because laser cutting has very high requirements for laser beam sources, not all lasers are suitable for the cutting process.

Cutting Head

The cutting head is mainly composed of nozzle, focus lens and focus tracking system.

1. Nozzles: There are three common nozzle forms on the market: parallel, convergent and conical.

2. Focusing lens: focus the energy of the laser beam and form a high-energy-density light spot. The medium and long focusing lens is suitable for cutting thick plates, and has low requirements for the stability of the tracking system. The short focus lens is only suitable for thin plate cutting. This kind of tracking system has a very high requirement on the pitch stability, and the laser output power requirement is greatly reduced.

3. Focus tracking system: The focus tracking system is generally composed of a focus cutting head and a tracking sensor system. The cutting head includes light guide focusing, water cooling, air blowing and mechanical adjustment parts. The sensor is composed of a sensing element and an amplifying control part. The tracking system is completely different according to the different sensing elements. Here, there are mainly two types of tracking systems, one is the capacitive sensor tracking system, also known as the non-contact tracking system. The other is the inductive sensor tracking system, also known as the contact tracking system.

Laser Beam Delivery Components

The main part of the beam delivery component is a refractive mirror, which is used to direct the laser light in the required direction. The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is passed in to protect the lens from contamination.

Machine Tool Table

The machine tool table is mainly composed of a weighing bed and a drive part, which is used to realize the mechanical part of the X, Y, and Z axis movement, and also includes the cutting table.

CNC System

The CNC system can mainly control the movement of the machine tool to the X, Y, and Z axes, as well as the power, speed and other parameters during cutting.

Cooling System

The cooling system is mainly a water chiller for cooling the laser generator. For example, the electro-optical conversion rate of the laser is 33%, and about 67% of the electric energy is converted into heat. In order to ensure the normal operation of the equipment, the chiller needs to reduce the temperature of the whole machine through water cooling.

6 Main Parts of A Fiber Laser Cutting Machine?

With the continuous improvement of people’s technological requirements, traditional welding can no longer meet the needs of customers. The emergence of a new generation of laser welding machines has promoted the development of welding technology, and the scope of application and industries have become more and more extensive. So, what components are needed to make a laser welding machine.

Laser

There are two main types of lasers for laser welding: CO2 gas laser and YAG solid laser. The most important performance of the laser is the output power and beam quality. The CO2 laser wavelength has a good absorption rate for non-metallic materials, while for metals, the YAG laser wavelength has a high absorption rate, which is very beneficial for metal welding.

Beam focusing system

The laser beam focusing system is a laser and optical processing component, usually composed of several lenses. Beam focusing system and various forms: parabolic mirror system, plane mirror system, spherical mirror system.

Beam transmission system

The beam transmission system is used to transmit and output laser sources, including beam expansion, beam manipulation, beam energy distribution, mirror transmission, optical fiber transmission, etc.

Shielding gas and nozzle structure

laser welding and arc welding need to be protected with inert gas to prevent oxidation and air pollution. Laser welding requires gas protection. In the laser welding process, these gases are output to the laser radiation area through a special nozzle to achieve a protective effect.

Tooling fixture

Laser welding fixture is mainly used to fix the welded workpiece, and make it can be repeatedly loaded and unloaded, repeated positioning, in order to facilitate the automatic laser welding, therefore, the tooling fixture is one of the essential equipment in laser welding production .

Observation system

Generally, the laser welding machine needs to be equipped with an observation system, which can perform real-time microscopic observation of the workpiece, which is used to facilitate accurate positioning when programming welding procedures and to check the welding effect during the welding process. Generally, it is equipped with a CCD display system or a microscope. .

Cooling system

The cooling system provides cooling function for the laser generator, generally equipped with a water circulation chiller with a power of 1-5 hp, (mainly for the welding machine of the square laser)

Cabinets, industrial computers

In addition to the above accessories, the laser welding machine also includes modules, columns, galvanometers, field lenses, four-volt drivers, boards, welding torque or cutting, workbenches, various power switches and control devices, air and water sources, It is composed of operation panel and numerical control device.

How to Choose A Suitable Fiber Laser Cutting Machine for Your Business?

What Are the Applications for Fiber Laser Metal Cutting Machine?

What Are the Differences between Fiber Laser Cutting, CO2 Cutting and CNC Plasma Cutting?

What Businesses Can I Expect from Laser Cutting and Laser Welding Tools?

Main Factors That Affect the Metal Laser Cutting Quality.

Quality First, but Pricing Matters: How Much Does A Laser Cutting Machine Cost?

What You Need to Know about Tube Laser Cutting Machines?

LEARN MORE ABOUT METAL LASER CUTTING MACHINES